Description

Sleeve Impact Press Snap Machine KM 700

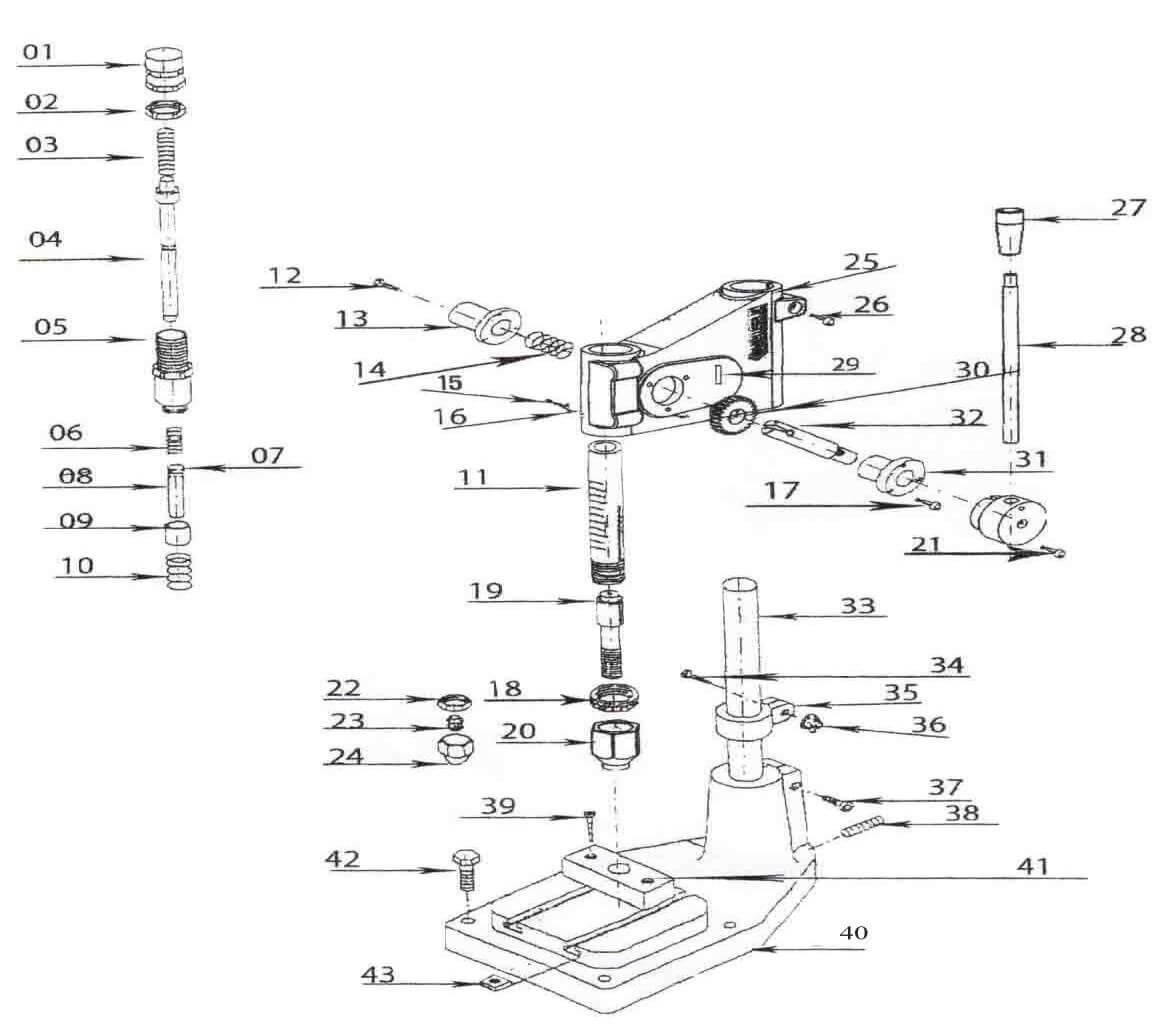

Our KM 700 lever impact press is made of cast iron and processed by our expert team on our cnc machines.

Our machine consists of two casting parts, height adjustment can be made.

The iron parts of our machine are produced by heat treatment and irrigation parts.

Our machine is very easy to use, the upper and lower mold after setting the center is ready to use after the center setting is made by loosening the allen screw located at the back of the upper body.

From here, only the left and right height adjustment is made from the apparatus to which the lower mold is connected to the front and back of the setting can be made after these settings after placing the material in the upper and lower slot can perform the nailing process.

Changing the pattern is a 1 minute process.

Maintenance of the machine is very simple up and down the shaft system with grease oil once a week we cleaned beautifully after the lubrication process is carried out by the Arm Pulse Press Snap Machine KM 700.

Applications

Advertisers, sign makers, banners, eyelet, textile manufacturers eyelet, rivet, button plating, hook, studs rivet, trop, costume, etc. in your business, in industry

Electrical and electronic assembly door and window assembly; Aluminum, blinds, packing etc. In your business, the traffic license plate is registered; marking and so on. work; used in automotive and printing, punching, punching, skirt bending, fastening, cosmetic and toy assembly.

With a single machine, you can use it by changing molds in all your works.

Sleeve Impact Press Snap Machine KM 700

Technicial Specifications

Impact Power: max. 1300 kg / cm2

Workpiece Height: 200 mm.

Column Diameter: Ø 36 mm.

Between Shafts: 140 mm

Table Width: 100 x 100

Collet Hole: Ø 9 mm.

T Channels: 8 H 12 DIN 650

Dimensions: 470 X 270 X 130

Weight: 21 kg.

Sleeve Impact Press Snap Machine KM 700

Our KM 700 lever impact press is made of cast iron and processed by our expert team on our cnc machines.

Our machine consists of two casting parts, height adjustment can be made.

The iron parts of our machine are produced by heat treatment and irrigation parts.

Our machine is very easy to use, the upper and lower mold after setting the center is ready to use after the center setting is made by loosening the Allen screw on the back of the upper body

From here, only the left and right height adjustment is made from the apparatus to which the lower mold is connected to the front and back.

Sleeve Impact Press Snap Machine KM 700

After these settings, you can perform the nailing process after placing your material in the upper and lower slot.

Changing the pattern is a 1 minute process.

Maintenance of the machine is very simple up and down the shaft system with grease oil once a week we cleaned beautifully after the lubrication process is carried out by the Arm Pulse Press Snap Machine KM 700.

BLOOD FENCE FENCE MACHINES MANUFACTURING CLICK HERE

Applications

Advertisers, sign makers, banners, eyelet, textile manufacturers eyelet, rivet, button plating, hook, studs rivet, trop, costume, etc. in your business, in industry

Electrical and electronic assembly door and window assembly; Aluminum, blinds, packing etc. In your business, the traffic license plate is registered; marking and so on. work; used in automotive and printing, punching, punching, skirt bending, fastening, cosmetic and toy assembly. With a single machine, you can use it by changing molds in all your works.

Sleeve Impact Press Snap Machine KM 700

Technicial Specifications

Impact Power: max. 1300 kg / cm2

Workpiece Height: 200 mm.

Column Diameter: Ø 36 mm.

Between Shafts: 140 mm

Table Width: 100 x 100

Collet Hole: Ø 9 mm.

T Channels: 8 H 12 DIN 650

Dimensions: 470 X 270 X 130

Weight: 21 kg.

Makes Kanmak Machine Accessory Fastening Machines.

Kanmak Machine Manufacturing – Online Sales with Kanmak Machine Assurance

Reviews

There are no reviews yet.